The grain in the growth, harvesting, threshing, storage and transportation process, there will be mixed with a variety of impurities, not only affect the quality of grain, grade and price, but also affect the processing technology and food quality.

Some unscrupulous traders will even deliberately mixed with a lot of impurities, shoddy, access to illegal interests.

Rapid impurity detector can quickly and accurately measure the various impurities in the food in one minute, and classify the impurities and classify the grain.

|

| www.hongdefa.com |

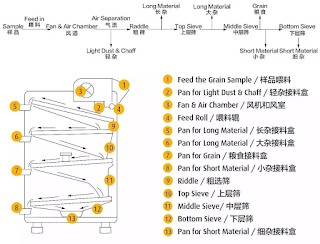

Working principle:

Grain samples through the feed port into the equipment, through the feed roller, wind chamber and other testing agencies, due to impurities and grain in the volume, suspension speed, particle size and friction coefficient are not the same, the use of wind selection, screening, grading and other technologies, The impurities and broken grain from the grain separated.

|

| www.hongdefa.com |

Functional use: rapid detection of grain containing the rate, the grain classification and so on.

Scope: grain and oil processing enterprises, grain reserves, grain purchasing and storage providers, grain testing and testing institutions, such as the Entry-Exit Inspection and Quarantine Bureau.

Applicable materials: wheat, barley, rapeseed, corn, rice, soybean, sunflower, flax, millet, lentils, mustard, oats, rye, safflower, sesame seeds and sorghum.

|

| www.hongdefa.com |

没有评论:

发表评论